THE SOLUTION IS CLEAR WHEN YOU

CAN SEE BEYOND THE PROBLEM

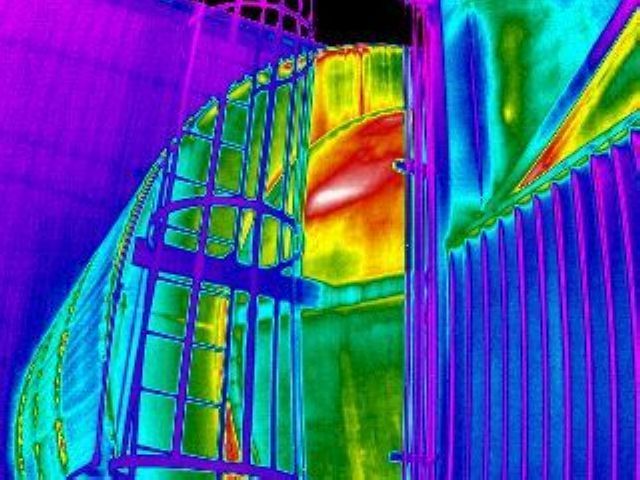

The usual way to inspect refractory material in kilns and furnaces is to stop the equipment, empty it and inspect the refractory visually

Thermal imaging enables the maintenance personnel to scan the kiln or furnace in real time while in operation, and deficiencies in the refractory will show as hot spots on the outer surface of the kiln.

Furthermore, this technology will enable the maintenance department to keep a history of the images showing deterioration over time and timing stoppages and repairs efficiently.

SOME OF THE VALUED CLIENTS WE WORK WITH

We Look Forward to Hearing From You